No valve for you today

I thought I wanted to remove my valves and valve seats. To do that, I needed a spring compressor tool. These things come in lots of shapes and sizes. Some of them look like a bent fork and rely on having the rocker arms in place (or at least the studs). Some of them look like a giant C-clamp that connects on both sides of valve. They rely on the heads being off. Some of them look like the Recognizer from the movie Tron - with a screw on top and hooks down the side. They range in price from: free for loan at the autoparts store to this thing with umpteen parts for $75.

I was going to borrow the one from the parts store - but it gave me the willys. I looked at it several times and kept coming to the conclusion that I was going to hate using that tool or get injured in the process. Oreilly's and Autozone loan the screw-hook Tron thing, but the hooks are not well designed for gripping a heavy duty spring. I am sure with a hose clamp to secure it I could make it work but I didn't want to try.

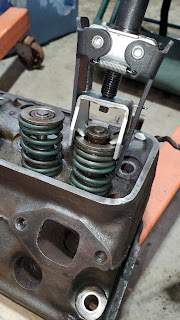

So, like a moth to a flame - I bought the one at Harbor Freight that was on clearance. Also the Tron machine, but it happened to work well. I think I was lucky in that the spring diameter was just about right for the way the hook arms were shaped.

I carefully put in place and screwed down the top to compress the spring.

Notice how real life doesn't look very much like the shop manual?

I was expecting that once the big flat retainer moved, the locks would be exposed and I would take them off with a magnetic pickup. Just like the manual says and just like YouTube said. Except I found another cup shaped retainer around the locks. I have a 2-piece spring retainer. I was not aware that was a thing. And - of course - burnt oil or crud is keeping it stuck to the locks. I need do it again and gently tap the inner retainer with a screw driver until it falls down.

NOTHING is easy. NOTHING goes like the book says. You are trapped in an existential black hole filled with rust and grease. And yes, the C clamp version is nicer... And yes, it is scary to have those springs compressed with the inate knowledge that it could all snap loose in your face with attendant re-arrangement of the features of your face. And pain.

ReplyDeleteI found I was sweating while I was turning the screw - way more than from the effort

DeleteDecades ago when I decided to work on my Dodge 440 V-8 engine, I got the heads off and paid a mechanic to remove valves and refurbish valve seats. Costs more, but much safer for me. Be very careful and rehearse each move before you make it.

ReplyDeleteI do find the need to pause - think about what I am doing next - what will come after that - and what could go wrong with that.

Delete